Sheet metal bending

Bending and forming of sheet metal: The bending and forming of metal plates are performed on a plate bending machine. The plate to be formed is placed on the plate bending machine, the brake pads are lifted with a lifting lever, the workpiece is slid to an appropriate position, and then the metal plate is bent. The moving piece is lowered to the sheet to be formed, and the bending of the metal is realized by applying force to the bending lever on the bending machine.

Process cost: standard mold cost (none), unit cost (low-medium)

Typical products: consumer electronics, packaging, transportation, construction metal parts, etc.

Suitable output: suitable for mass production (not more than 5000 pieces), also can be customized individually

Quality: high bending accuracy, the error is about 0.1mm (0.004in)

Speed: 6 bends per minute, but the initial configuration of the bending machine will take a long time

Applicable materials

Suitable for almost all metal materials, the most commonly used materials are: steel, aluminum, copper and titanium, etc.

Design considerations

1. Single piece bending length can be up to 16m (52ft)

2. The path of metal bending can only be a straight line

3. The radius of the inner corner of the bend of the ductile material is 1 times the thickness of the sheet, and the radius of the inner corner of the bend of the hard material is 3 times the thickness of the sheet

4. If the metal sheet has not been heat treated, the thickness of the bending can be up to 50mm (2in).

Detailed process

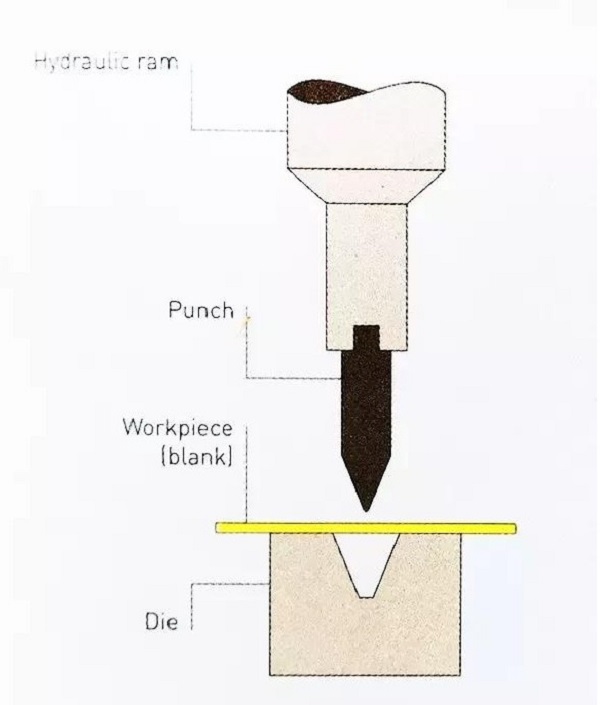

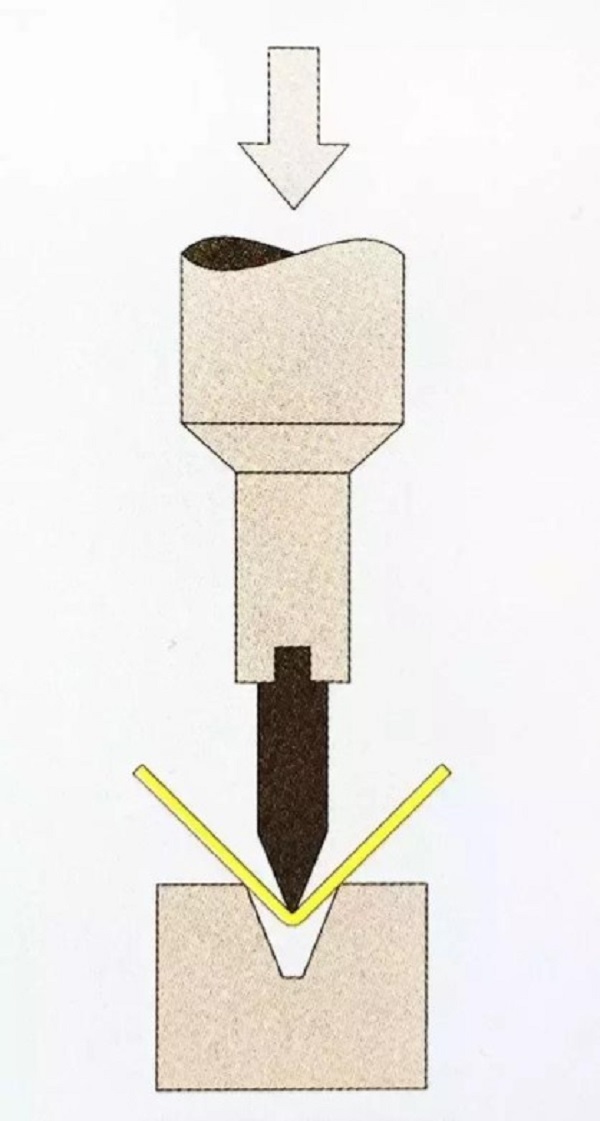

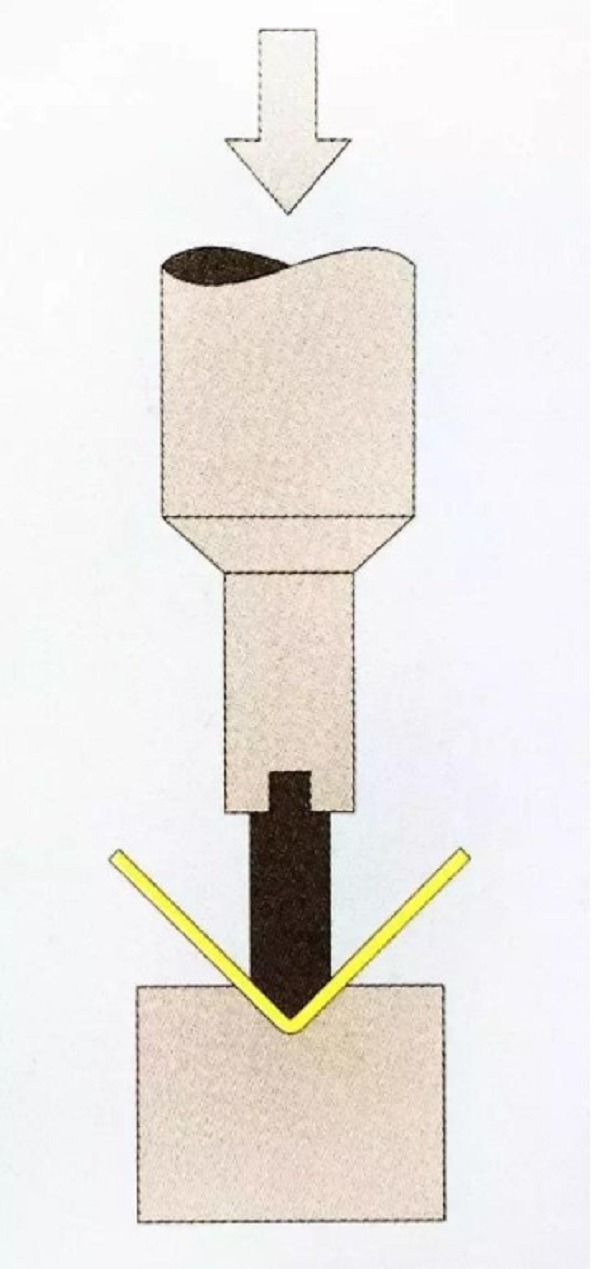

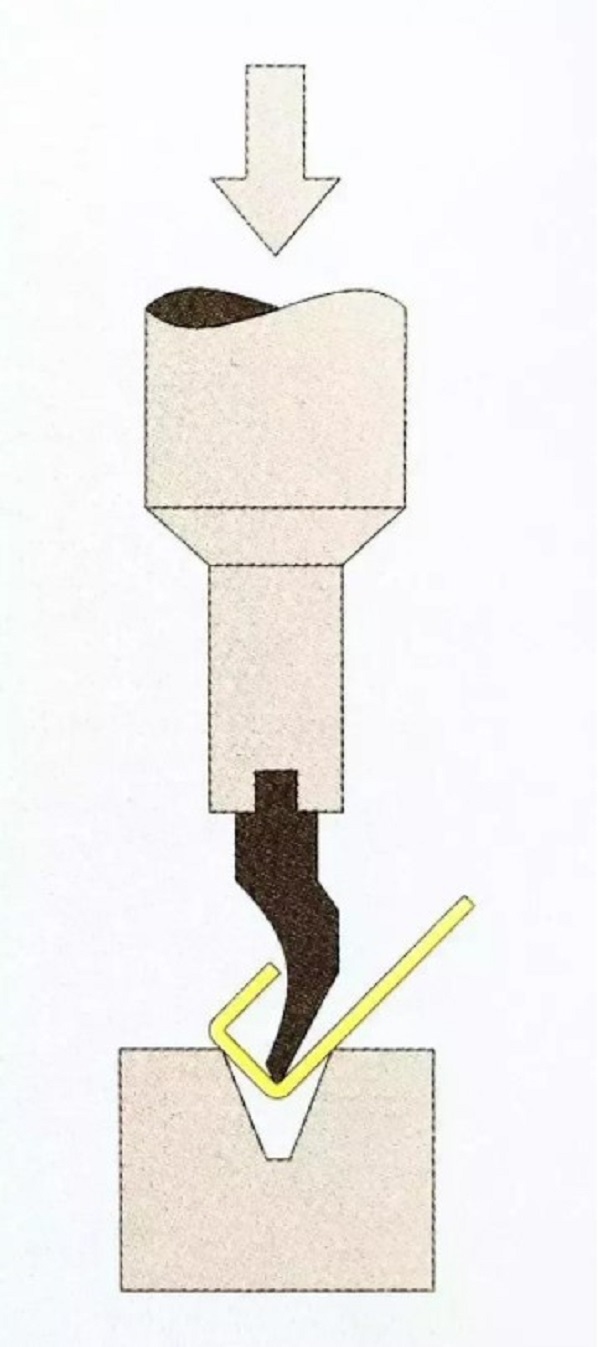

The punch is driven by a hydraulic cylinder (providing vertical pressure), and the pressure is determined by 4 factors: bending length, sheet thickness, ductility and bending radius.

Step 1: Place the prepared sheet metal part on a hard mold

Step 2: The punch is driven by a hydraulic cylinder to press the sheet metal part to bend and form. Each bending takes only a few seconds, and the whole process is controlled by the computer.

The shape of the sheet metal bend is determined by the punch model and the hard mold model, which are divided into standard molds and non-standard molds.