Vacuum heat treatment

What is vacuum heat treatment processing technology?

Refers to a new type of heat treatment technology that combines vacuum technology and heat treatment technology. Among them, the vacuum environment in which vacuum heat treatment is located refers to an atmosphere environment that is lower than one atmosphere, including low vacuum, medium vacuum, high vacuum, and ultra high vacuum. Therefore, the vacuum heat treatment actually belongs to the atmosphere controlled heat treatment.

Vacuum heat treatment means that all and part of the heat treatment process is performed under vacuum. Vacuum heat treatment can realize almost all the heat treatment processes that can be involved in conventional heat treatment, but the quality of heat treatment is greatly improved.

Compared with conventional heat treatment, vacuum heat treatment processing technology can simultaneously achieve no oxidation, no decarburization, no carburization, can remove phosphorus debris on the surface of the workpiece, and has the effect of degreasing and degassing, so as to achieve a bright surface purification effect.

Application of vacuum heat treatment processing technology

In fact, vacuum heat treatment processing technology was applied earlier in the world. In 1968, the Hayes Company in the United States and the Japan Vacuum Research Institute successively developed vacuum quenching oil and water-based quenching media. Therefore, the vacuum quenching technology has developed rapidly in the heat treatment industry. From single-chamber furnace to multi-combined machine group, from general vacuum quenching to high-pressure gas quenching, vacuum water quenching, vacuum carburizing, vacuum carbonitriding, and multiple co-infiltration.

After decades of efforts in China, manufacturers of vacuum furnaces have greatly improved their design, manufacturing level and quality. The use of domestic vacuum equipment to replace imported vacuum equipment has gradually increased, thereby reducing the production of units. The cost makes the application range of vacuum heat treatment rapidly expand.

Process principle of vacuum heat treatment

Taking advantage of the phase transformation characteristics of metals in a vacuum state, under a vacuum within 0.1 MPa difference from atmospheric pressure, there is no change in the thermodynamics and dynamics of solid phase transformation. When formulating the vacuum heat treatment process specification, it can be based on the principle of solid-state phase change under normal pressure, and can refer to the data of various types of tissue transformation under normal pressure.

At the same time, under the action of vacuum degassing, the physical and mechanical properties of metal materials can be improved. When heating under vacuum, the elements on the surface of metal workpieces will evaporate. The degree of vacuum required for the metal to achieve non-oxidative heating, surface purification, and less oxidation and less desorption.

Characteristics of vacuum heat treatment processing technology

1) Advantages of vacuum heat treatment

Vacuum heat treatment is a wide range of non-oxidation heat treatment technology that can go hand in hand with a controlled atmosphere. It is also one of the main signs of the advanced level of current heat treatment production technology. Vacuum heat treatment can not only achieve the non-oxidation and decarburization of steel parts, but also the production of pollution-free and less distortion of the workpiece, so it also belongs to the category of clean and precision production technology. At present, it has become an irreplaceable advanced technology in tool and mold production.

2) Less distortion of the workpiece in the vacuum heat treatment process

According to domestic and foreign experience, the distortion of the vacuum heat treatment of the workpiece is only one-third of the salt bath heating and quenching. It is of great significance to study the vacuum heating methods of various materials and parts with different degrees of complexity and the distortion laws under various cooling conditions, and use computer simulations to promote the vacuum heat treatment technology. When vacuum heating, normal pressure or high pressure air-cooling quenching, the uniformity of air flow has a great influence on the hardening effect and quality dispersion of the parts. It is of great significance to improve the structure of the furnace by using computer simulation methods to study the air circulation law in the furnace.

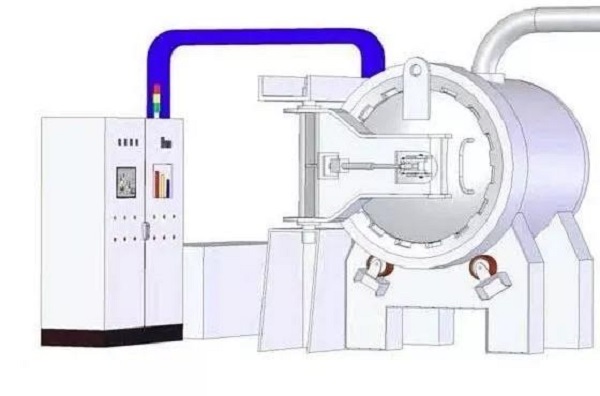

3) Vacuum heat treatment furnace

Modern vacuum heat treatment furnaces refer to cold-wall furnaces that can perform vacuum heating of components and then quench in oil or in atmospheric and pressurized gases. Research and development of this type of equipment is a comprehensive, interdisciplinary, and involves many scientific and technological fields.

In the field of tool and die materials, the application of vacuum heat treatment is very promising. Most tool steels are currently heated in a vacuum and then cooled and quenched in a gas. In order to obtain satisfactory mechanical properties on the surface and inside of the workpiece, vacuum high pressure gas quenching technology must be used. At present, the pressure of vacuum gas quenching in the world has increased from 0.2 MPa, 0.6 MPa to 1-2 MPa or even 3 MPa. Therefore, the gradual increase of the cooling gas pressure of the high pressure gas quenching vacuum furnace is an important development trend.