Processing method of eccentric parts

1. The traditional method of processing eccentric parts

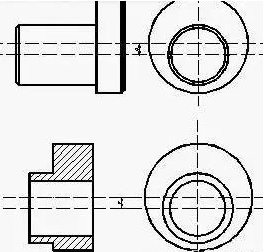

An eccentric workpiece is a workpiece whose outer circle and outer circle or the axis of the outer circle and the inner hole are parallel and not coincident, and are offset by a distance. The distance between these two parallel axes is called the eccentricity. Parts with eccentric outer circle and outer circle are called eccentric shaft or eccentric disc; parts with eccentric outer circle and inner hole are called eccentric sleeve. as the picture shows.

In mechanical transmission, the rotary motion becomes the reciprocating linear motion or the reciprocating linear motion becomes the rotary motion, which is generally done by using eccentric parts. For example, the lubrication pump driven by the eccentric workpiece in the headstock of the lathe, the crankshaft in the automobile engine, etc.

Eccentric shafts and eccentric sleeves are generally processed on a lathe. Their machining principles are basically the same; the main thing is to take measures in clamping, that is, to align the axis of the eccentric part to be machined to coincide with the axis of rotation of the lathe spindle. There are generally 5 methods for turning eccentric workpieces, that is, turning the eccentric workpiece on the three-jaw chuck, turning the eccentric workpiece on the four-jaw chuck, turning the eccentric workpiece between the two centers, and turning the eccentric workpiece on the eccentric chuck. The fixture loads the eccentric workpiece.

2. Process analysis of traditional car eccentric parts

Turning method

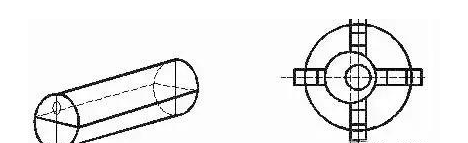

Eccentric workpieces with short lengths can be turned on a three-jaw chuck. First turn the outer circle of the non-eccentric part of the eccentric workpiece, and then place a pre-selected shim between any of the jaws of the chuck and the joint surface of the workpiece. The bus bar and the eccentric distance are corrected, and the After the workpiece is clamped, it can be turned.

The thickness of the gasket can be calculated by an approximate formula; the thickness of the gasket X = 1.5e (eccentricity). If the calculation is more accurate, the eccentricity correction value k must be added to the approximate formula to calculate and adjust the gasket thickness. The approximate formula is: gasket thickness x=1.5e+k

Measurement and inspection of eccentric workpieces

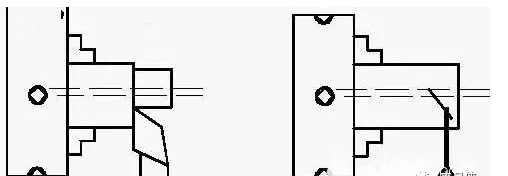

When adjusting and correcting the side bus bar and eccentricity of the workpiece, it is mainly carried out on a lathe with a dial indicator with a magnetic meter seat (as shown in the figure (c) right), until it meets the requirements before turning. After the workpiece is turned, in order to determine whether the eccentricity meets the requirements, a final inspection is required. The method is to put the workpiece in the v-shaped iron, measure it at the eccentric circle with a dial indicator, slowly rotate the workpiece, and observe the amount of runout.

2. Use four-jaw single-action chuck for clamping

Mount the marked workpiece on a four-jaw chuck. When clamping, adjust the two jaws of the chuck to make them asymmetrical, and the other two jaws are symmetrical. The eccentric circle line of the workpiece is in the center of the chuck (see the above right)

Put a small flat plate and a needle plate on the bed, and align the needle tip with the eccentric circle line to correct the eccentric circle. Then align the needle tip to the horizontal line of the outer circle, as shown on the left in the figure below, and check whether the horizontal line is level from left to right. Rotate the workpiece by 90°, check another horizontal line in the same way, then tighten the clamping feet and review the clamping of the workpiece.

After the workpiece is calibrated, tighten the four jaws again to start cutting. In the initial cutting, the feed rate should be small and the cutting depth should be shallow. After the workpiece is rounded, the cutting amount can be increased appropriately, otherwise the turning tool will be damaged or the workpiece will be displaced. As shown below (c) left:

The above two methods are relatively common processing methods, but both have disadvantages. Clamping is more troublesome, not easy to align, and easy to produce errors. And it is not suitable for mass production. Due to the above shortcomings, I designed an eccentric fixture specially used for mass production. And put into production, to achieve a certain effect.

3. Design of new special eccentric fixture

The eccentric wheel car fixture is mainly used for mass production of eccentric parts. The parts diagram of the fixture is attached below (see Figure 1).

Calibrate the Ф60 inner hole during clamping to ensure the tolerance requirements of the part shape and position. The clamping method is to clamp the workpiece on the left end of the clamp as shown in the figure below, correct it with a dial indicator, and clamp the right end on the three-jaw self-centering chuck.