Hole processing

The hole is an important surface on the box, bracket, sleeve, ring, disk and other parts, and it is also a surface often encountered in mechanical processing. In the case where the machining accuracy and surface roughness requirements are the same, machining holes is more difficult than machining external surfaces, and the productivity is low and the cost is high.

This is because: 1) the size of the tool used for hole processing is limited by the size of the hole being processed, and the rigidity is poor, which is prone to bending deformation and vibration; 2) when processing a hole with a fixed-size tool, the size of the hole processing often depends directly on the tool Corresponding size, tool manufacturing error and wear will directly affect the machining accuracy of the hole; 3) When machining the hole, the cutting area is inside the workpiece, the chip removal and heat dissipation conditions are poor, and the machining accuracy and surface quality are not easy to control.

一、Drilling and reaming

1.Drilling

Drilling is the first procedure for machining holes in solid materials. The diameter of the hole is generally less than 80mm. There are two ways of drilling: one is the rotation of the drill bit; the other is the rotation of the workpiece. The errors produced by the above two drilling methods are different. In the drilling method in which the drill bit rotates, the centerline of the hole to be processed may be deviated or deviated due to the asymmetry of the cutting edge and the insufficient rigidity of the drill bit. Not straight, but the hole diameter is basically unchanged; while in the drilling method of workpiece rotation, the opposite is true. The deviation of the drill bit will cause the hole diameter to change, while the hole centerline is still straight.

Commonly used drilling knives are: twist drills, center drills, deep hole drills, etc., the most commonly used is twist drills, the diameter of which is Φ0.1-80mm.

Due to structural limitations, the bending stiffness and torsional stiffness of the drill are low, and the centering is not good, and the accuracy of drilling is low, generally only reaching IT13~IT11; the surface roughness is also large, Ra is generally 50 ~12.5μm; but the metal removal rate of the hole is large and the cutting efficiency is high. Drilling is mainly used to process holes with low quality requirements, such as bolt holes, threaded bottom holes, oil holes, etc. For the holes with high processing accuracy and surface quality requirements, they should be achieved by reaming, reaming, boring or grinding holes in subsequent processing.

2. Reaming

Reaming is to further process the holes that have been drilled, cast or forged with a reaming drill to expand the hole diameter and improve the processing quality of the hole. The reaming process can be used as a pre-processing before finishing the hole, or as The final processing of holes that are not demanding. Reaming drills are similar to twist drills, but they have more cutter teeth and no transverse edges.

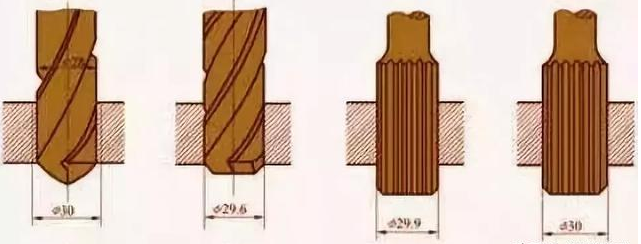

Compared with drilling, reaming has the following characteristics: (1) The number of teeth of the reaming drill is large (3-8 teeth), the guidance is good, and the cutting is relatively stable; (2) The reaming drill has no transverse edge and the cutting conditions are good; (3) The machining allowance is small, the chip flute can be made shallower, the drill core can be made thicker, and the cutter body has better strength and rigidity. The precision of reaming processing is generally IT11~IT10, and the surface roughness Ra is 12.5~6.3μm. Reaming is commonly used to machine holes with a diameter smaller than. When drilling a hole with a larger diameter (D ≥ 30mm), it is often pre-drilled with a small drill (the diameter is 0.5 to 0.7 times the hole diameter), and then the hole is drilled and expanded with the corresponding size, which can increase the hole Processing quality and production efficiency.

In addition to processing cylindrical holes, reaming can also use a variety of special shape reaming drills (also known as countersinks) to process a variety of countersunk seat holes and countersink flat end surface. The front end of the countersink is often provided with a guide post, which is guided with a machined hole.

二、Reaming

Reaming is one of the finishing methods for holes and is widely used in production. For smaller holes, reaming is a more economical and practical processing method than internal grinding and precision boring.

1.Reamer

Reamers are generally divided into two types: hand reamers and machine reamers. The handle of the hand reamer is a straight shank, the working part is longer, and the guiding effect is better. The hand reamer has two structures of integral type and adjustable outer diameter. Machine reamer has two structures with handle and sleeve. The reamer can not only process circular holes, but also taper reamer to process tapered holes.

2. Reaming process and its application

The reaming allowance has a great influence on the quality of the reaming, the allowance is too large, the load of the reamer is large, the cutting edge is quickly blunt, it is not easy to obtain a smooth machining surface, and the dimensional tolerances are not easy to guarantee; the allowance is too small, Can not remove the knife marks left by the previous process, naturally there is no role in improving the quality of hole processing. Generally, the margin of coarse hinge is 0.35~0.15mm, and that of fine hinge is 01.5~0.05mm.

In order to avoid built-up edge, the reaming hole is usually processed at a lower cutting speed (v <8m/min when processing steel and cast iron with high-speed steel reamer). The value of the feed rate is related to the aperture to be processed. The larger the aperture, the greater the value of the feed rate. When the steel and cast iron are processed by the high-speed steel reamer, the feed rate is usually 0.3 to 1 mm/r.

Reaming must be cooled, lubricated and cleaned with appropriate cutting fluid to prevent the build-up edge and remove chips in time. Compared with grinding and boring, reaming productivity is high, and it is easy to ensure the accuracy of the hole; but reaming cannot correct the position error of the hole axis, and the position accuracy of the hole should be guaranteed by the previous process. Reaming holes are not suitable for processing stepped holes and blind holes.

The reaming hole size accuracy is generally IT9~IT7, and the surface roughness Ra is generally 3.2~0.8 μm. For holes of medium size and high precision requirements (such as IT7 precision holes), the drilling-expanding-reaming process is a typical processing scheme commonly used in production.

三、Boring

Boring is a processing method that uses cutting tools to expand the pre-made holes. The boring work can be performed on the boring machine or the lathe.

1. Boring method

There are three different processing methods for boring.

1) The workpiece rotates, and the tool makes a feed motion

Most of the boring on the lathe belongs to this boring method. The technical characteristics are: the axis of the hole after processing is consistent with the rotation axis of the workpiece, the roundness of the hole mainly depends on the rotation accuracy of the machine tool spindle, and the axial geometric error of the hole mainly depends on the tool feed direction relative to the rotation axis of the workpiece Position accuracy. This boring method is suitable for processing holes that have coaxiality requirements with the outer circular surface.

2) The tool rotates and the workpiece moves in feed

The spindle of the boring machine drives the boring tool to rotate, and the worktable drives the workpiece to feed.

3) The tool rotates and feeds

With this method of boring, the overhanging elongation of the boring bar is changed, and the force deformation of the boring bar is also changed. The hole diameter near the headstock is large, and the hole diameter away from the headstock is small, forming a tapered hole. In addition, the overhanging elongation of the boring bar is increased, the bending deformation of the main shaft due to its own weight is also increased, and the axis of the processed hole will be bent accordingly. This boring method is only suitable for machining shorter holes.

2. Diamond boring

Compared with general boring, diamond boring is characterized by small back-feeding, small feed, and high cutting speed. It can obtain very high machining accuracy (IT7~IT6) and a very smooth surface (Ra is 0.4~ 0.05 μm). Diamond boring was initially processed with diamond boring tools, and now carbide, CBN and synthetic diamond tools are commonly used. Mainly used for processing non-ferrous metal workpieces, but also for processing cast iron and steel parts.

The cutting amount commonly used for diamond boring is: the amount of back-feeding pre-boring is 0.2~0.6mm, the final boring is 0.1mm; the feed rate is 0.01~0.14mm/r; the cutting speed is 100~250m/min when processing cast iron, processing 150~300m/min for steel and 300~2000m/min when processing non-ferrous metals.