Why use a cam?

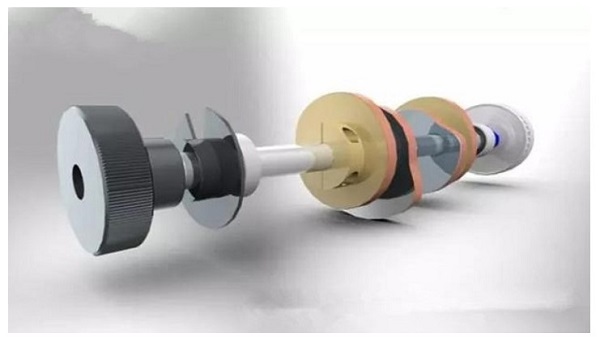

The cam mechanism is a high-pair mechanism composed of three basic components: a cam, a follower, and a frame. The cam is a member with a curved profile or groove. Generally, it is a master, which performs constant-speed rotary motion or reciprocating linear motion.

Just by designing the proper cam profile, the follower can get any desired movement, and the structure is simple, compact and convenient to design. Therefore, it is suitable for automatic machine tools, light industry machinery, textile machinery, printing machinery, food machinery, packaging machinery and It is widely used in mechatronic products. The biggest advantage of the cam mechanism is that it can achieve high speed, compact structure and high reliability; the biggest disadvantage is that it is immutable and cannot change the operating time (angle).

A customer had previously developed a device with a pure cam structure, designed a lot of special-shaped cams, and the output was much higher than the previous old models; and many seniors also said so, and many foreign equipment they came into contact with were also Is such that.

The cam design should be divided into three steps. The first step is to determine the parameters, that is, to determine the various initial parameters of the cam according to the action requirements of the follower. Take the swing follower cam as an example, such as the cam rotation speed, swing lever length, and minimum. And the maximum theoretical contour radius, the center position of the pendulum, the direction of cam rotation, if there is a conjugate, there are parameters such as the angle between the main and auxiliary pendulums.

The second step is the cam curve design. For example, a car travels from A to B. The distance (the length of the distance is determined in the first step) is constant. The speed and time are controlled by the driver. In the end, do you want to save fuel, or do you want to be safe, or fast, or do you want less car wear? This requires the driver to take control. There are so many requirements to be weighed against each other. There is no best. Only according to the requirements, which one is more reasonable and closer to the ideal. When designing the cam, we are the driver, and we must design a most reasonable cam curve to meet the requirements of working conditions. The relationship between cam and cam curve: The cam is actually a component with an irregular contour, and the cam curve is the movement curve of the follower. The design purpose of the cam curve is to make the follower under the premise of meeting the mechanical movement. Go as smooth as possible, without vibration, and consume less energy. For our usual design of cams, the general cam curve, if only the final position of the follower is required, the sine curve is even a good choice, and you can also choose to modify the sine and trapezoid. Of course, there are also requirements for the speed, acceleration and even jerk of the follower at a certain point in time.

Although this situation is rare, I really encountered that it takes a long time to calculate and requires mathematical skills to design. In fact, the wider application of cam curves should be on servo motors, except that we learn mechanically called cam curves, and servo motors are called curves. Weigh the maximum speed, maximum acceleration, time, vibration, load, motor In the process of current, pulse frequency, etc., a best motion curve is designed.

In the third step, the cam design calculates the maximum load on the cam surface according to the maximum speed, maximum acceleration, moment of inertia and other values calculated in the second step, and then according to the cam's rotation speed, lubrication conditions, operating temperature, and cam The material (usually a roller) of the contacting part, choose a reasonable material, thickness, heat treatment method, etc. Of course, the cam design also needs to consider the machining zero position, the assembly zero position, the easy adjustment, and the follower to disassemble easily. If it is an elastically closed cam, the life of the spring must also be considered.