Mechanical seal failure analysis

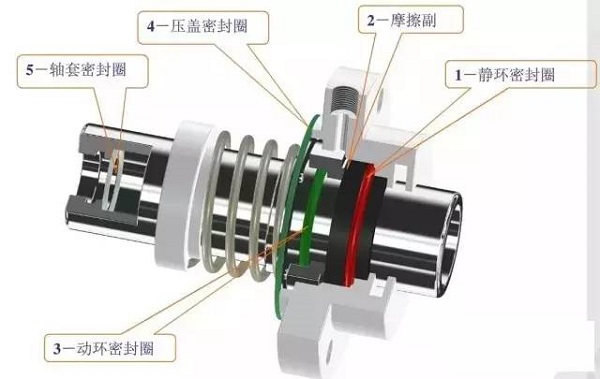

There are many types of mechanical seals for pumps, with different models, but there are five main leak points: (l) the seal between the shaft sleeve and the shaft; (2) the seal between the moving ring and the shaft sleeve; (3) the seal between the dynamic and static ring (4) the seal between the static ring and the static ring seat; (5) the seal between the sealing end cap and the pump body.

1. Leakage during installation static test

After the mechanical seal is installed and debugged, a static test is generally performed to observe the leakage. If the amount of leakage is small, there are usually problems with the dynamic or static ring seals; when the amount of leakage is large, it indicates that there is a problem between the friction pairs of the dynamic and static rings. Based on the preliminary observation of the leakage and the location of the leak, then manual cranking observation, if there is no significant change in the leakage, there are problems with the static and dynamic ring seals; if there is a significant change in the leakage during cranking, it can be determined that the There is a problem with the static ring friction pair. If the leakage medium is sprayed in the axial direction, the moving ring seals are mostly defective. If the leakage medium is sprayed around or leaks out of the water cooling hole, the static ring seals are mostly ineffective. In addition, the leakage channel can also exist at the same time, but there are generally primary and secondary differences. As long as you observe carefully and are familiar with the structure, you can certainly judge correctly.

2. Leaks during commissioning

The centrifugal force generated by the high-speed rotation of the mechanical seal for the pump after the static test will suppress the leakage of the medium. Therefore, the mechanical seal leakage during the trial operation is basically due to the damage of the dynamic and static ring friction pairs after the failure between the shaft and the end cap seal is eliminated. The main factors that cause the failure of the friction pair seal are: (l) During operation, abnormal axial phenomena such as evacuation, cavitation, and pressure will cause a large axial force to separate the contact surfaces of the dynamic and static rings; (for the installation of mechanical seals) When the amount of compression is too large, the end face of the friction pair is severely worn and abraded; (3) The moving ring seal is too tight, and the spring cannot adjust the axial floating amount of the moving ring; (4) The static ring seal is too loose. When the axis floats, the static ring breaks away from the static ring seat; (5) there is particulate matter in the working medium, friction pairs are entered during operation, flaw detection, and the static ring seals the end face; (6) the design selection is wrong, the seal end face ratio Low pressure or large shrinkage of the seal material, etc. The above phenomenon often occurs during trial operation, and can sometimes be eliminated by adjusting the static ring seat, etc., but most of them need to be disassembled and replaced to replace the seal.

3. Failure caused by loss of lubricating film on both seal faces

(a) Dry friction occurs due to the presence of the end face seal load when the pump is started when the seal chamber lacks liquid;

(b) The pressure of the medium below the saturated vapor causes flashing of the liquid film on the end face and loss of lubrication;

(c) If the medium is a volatile product, when scaling or blockage occurs in the mechanical seal cooling system, the saturated vapor pressure of the medium will rise due to the friction between the end face and the heat generated by the rotating element stirring the liquid, which will also cause the medium pressure to be lower than its saturation The condition of the vapor pressure.

4. Mechanical seal failure due to corrosion

(a) Pitting or even penetration of the sealing surface.

(b) Because the tungsten carbide ring is welded to the stainless steel base, the stainless steel base is prone to intergranular corrosion during use;

(c) Welded metal bellows, springs, etc. are prone to cracking under the combined action of stress and medium corrosion.

5. Mechanical seal failure due to high temperature effect

(a) Thermal cracking is the most common failure phenomenon of high temperature oil pumps, such as oil residue pumps, refining oil pumps, and atmospheric and vacuum tower bottom pumps. Due to dry friction at the sealing surface, sudden interruption of cooling water, impurities entering the sealing surface, evacuation, etc., will cause radial cracks on the torus surface;

(b) Graphite carbonization is one of the main causes of seal failure when using carbon-graphite rings. Because in use, if the graphite ring exceeds the allowable temperature (generally at -105 ~ 250 ℃), resin will precipitate on its surface, and the resin will be carbonized near the friction surface. When there is a binder, it will foam and soften. Increase the leakage of sealing surface and seal failure;

(c) Auxiliary seals (such as fluoro rubber, ethylene-propylene rubber, and all-rubber) will rapidly age, crack, harden and lose elasticity after exceeding the allowable temperature. The flexible graphite used now has high temperature and corrosion resistance, but its resilience is poor. It is also brittle and easily damaged during installation.

6. Seal failure due to abrasion of seal face

(a) The material used in the friction pair has poor abrasion resistance, large friction coefficient, and excessive end face specific pressure (including spring specific pressure), etc., which will shorten the service life of the mechanical seal. For the commonly used materials, the order of wear resistance is: silicon carbide-carbon graphite, cemented carbide-carbon graphite, ceramics-carbon graphite, sprayed ceramics--carbon graphite, silicon nitride ceramics--carbon graphite, high-speed steel --Carbon graphite, surfacing carbide--Carbon graphite.

(b) For media containing solid particles, the entry of sealing surfaces into solid particles is the main cause of seal failure. The solid particles enter the end face of the friction pair and act as an abrasive, causing severe wear and failure of the seal. Reasonable clearances on the sealing surface, the balance of the mechanical seal, and flash evaporation of the liquid film on the sealing end face are all the main causes of the end face opening and solid particles entering.

(c) The degree of balance β of the mechanical seal also affects the wear of the seal. In general, the degree of balance β = 75% is most appropriate. β <75%, although the amount of wear is reduced, the leakage is increased, and the possibility of the sealing surface opening is increased. For high load (high PV value) mechanical seals, due to the large frictional heat on the end face, β is generally 65% to 70%. For low boiling hydrocarbon media, etc., because the temperature is more sensitive to the gasification of the medium, in order to reduce The influence of frictional heat, β is preferably 80% to 85%.

7. Mechanical seal leakage due to errors caused by installation, operation or the equipment itself

(a) Mechanical seal leaks due to poor installation. It is mainly manifested in the following aspects:

(1) The contact surfaces of the dynamic and static rings are uneven, and they are injured or damaged during installation;

(2) The dimensions of the dynamic and static ring seals are incorrect, damaged or not compressed;

(3) Foreign matter on the surface of the dynamic and static rings;

(4) Install the dynamic and static ring V-rings in the opposite direction, or reverse the sides when installing;

(5) The shaft sleeve leaks, the sealing ring is not installed or the pressing force is insufficient;

(6) The spring force is not uniform, the single spring is not vertical, and the length of multiple springs is different;

(7) The perpendicularity between the end face of the sealing cavity and the shaft is not enough;

(8) There is a corrosion point at the movable part of the seal ring on the shaft sleeve.

(b) The main reasons for the leakage of the mechanical seal during the operation of the equipment are:

(1) The axial displacement of the pump impeller exceeds the standard, periodic vibration of the shaft and unstable process operation, and frequent changes in the pressure in the seal cavity will cause the seal to leak periodically;

(2) The friction pair is damaged or deformed and cannot run in to cause leakage;

(3) Improper selection of sealing ring materials, swelling and loss of elasticity;

(4) The large spring is not turning properly;

(5) The vibration of the equipment is too large;

(6) The scale between the dynamic and static rings and the shaft sleeve causes the spring to lose its spring and cannot compensate for the wear of the sealing surface;

(7) The seal ring is cracked.

(c) Leakage occurs when the pump is restarted after being stopped for a period of time. This is mainly due to the solidification and crystallization of the medium near the friction pair. The friction pair has scale, spring corrosion and blockage, and has lost its spring.