Knowledge of mechanical design

1. What are the reasons and measures to prevent loosening of threaded connections?

The reason is that under the effect of shock, vibration and variable load, the pre-tensioning force may disappear at a certain moment, the connection may be loosened, and the high-temperature screw connection may also loose due to the temperature deformation difference. Therefore, anti-loosening must be considered in the design. Measures-Use additional friction to prevent loosening, such as slotted nuts and cotter pins, retaining washers, etc. Other methods to prevent loosening, such as punching point method to prevent loosening, adhesive method to prevent loosening.

2. Measures to improve bolt connection strength

(1) Decrease the variation range of the total tensile load Fa of the bolt: a. In order to reduce the stiffness of the bolt, the diameter of the polished rod part can be reduced or a hollow screw can be used, or the length of the screw can be increased. B, the rigidity of the joint itself is relatively large. However, if the joints between the links need to be sealed, the rigidity will be reduced when a soft gasket is used. If a metal thin gasket or an O-ring is used as the sealing element, the original stiffness value of the connected parts can still be maintained.

(2) Improve the load distribution between threads,

(3) reduce stress concentration,

(4) Avoid or reduce additional stress.

3. Gear tooth failure form

(1) Gear tooth breakage generally occurs at the root part, because the root root bending stress is the largest when the gear tooth is stressed, and there is stress concentration, which can be divided into overload breakage and fatigue breakage.

(2) Pitting of tooth surface.

(3) The tooth surface is glued.

(4) The tooth surface is worn.

(5) Plastic deformation of tooth surface.

4. Gear transmission lubrication

Open gear transmission usually uses manual periodic oil lubrication. Lubricating oil or grease can be used. Generally, the lubrication method of closed gear transmission depends on the peripheral speed V of the gear. When V <= 12, oil pool lubrication is usually used. When V> 12, oil pool lubrication is not suitable. This is because (1) the peripheral speed is too high, and most of the oil on the gear is thrown out to reach the meshing zone. Increasing and reducing the lubricating performance. (3) It will stir up the impurities deposited on the bottom of the box and accelerate the wear of the gear. Oil injection lubrication is often used.

5. Why do worm gears perform heat balance calculations and cooling measures?

Due to the low transmission efficiency and high heat generation of the worm, if the heat is not released in time, it will cause the oil temperature in the box to rise, the lubrication failure, the gear wear will increase, and even gluing will occur. Therefore, the continuous work of the closed worm drive must be calculated for thermal balance.

Measures: (1) increase the heat dissipation area, rationally design the box structure, cast or weld fins, (2) increase the surface heat transfer coefficient, install a fan on the worm shaft, or install a serpentine in the oil tank of the box Cooling water pipe.

6. Advantages and disadvantages of belt drive

advantage

(1) Suitable for transmission with large center distance

(2) The belt has good flexibility, which can reduce impact and absorb vibration

(3) Slip between belt and pulley during overload, to prevent damage to other parts

(4) Simple structure and low cost.

Disadvantage

(1) The outer size of the transmission is large

(2) Tensioning device required

(3) Due to the sliding of the belt, a fixed transmission ratio cannot be guaranteed

(4) Short belt life

(5) The transmission efficiency is low.

7. Definition of elastic sliding and slipping

Elastic sliding refers to sliding caused by elastic deformation of a material. Slip is full slip caused by overload. Elastic sliding is caused by the difference in tensile force. As long as the circumferential force is transmitted, tight edges and loose edges appear, elastic sliding must occur. Therefore, elastic sliding is inevitable, and V2 is always greater than V1.

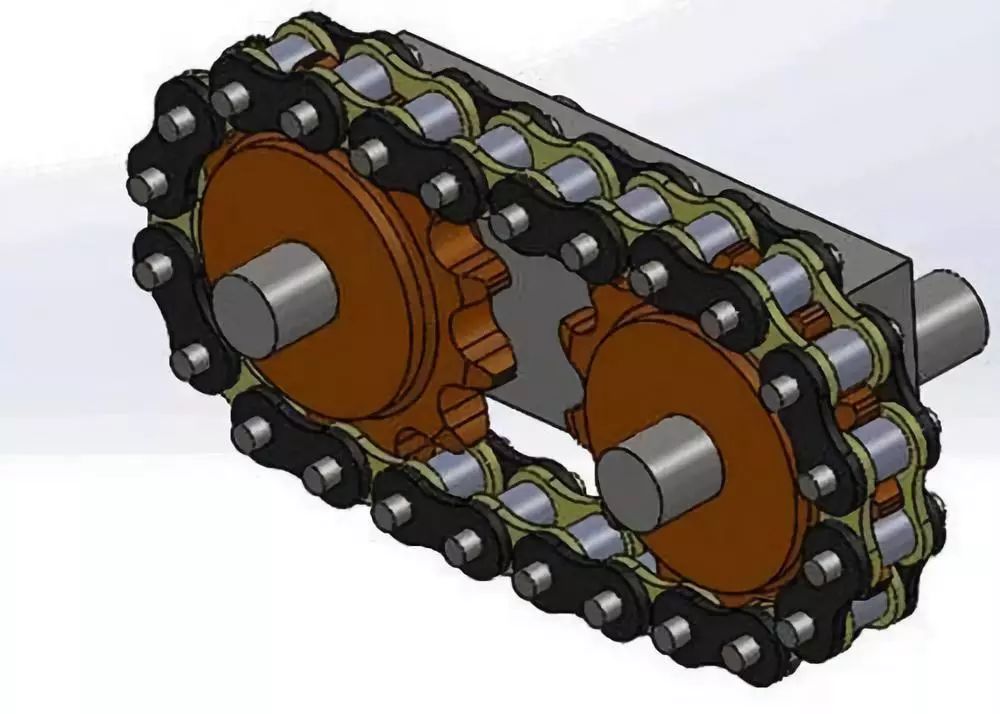

8. Advantages and disadvantages of chain drive compared to belt drive and gear drive

Compared with the belt drive, the chain drive does not have elastic sliding and slipping, can maintain an accurate average transmission ratio, requires less tension, and has less pressure on the shaft, which can reduce the friction loss of the bearing. Work under severe environmental conditions such as high temperature and oil pollution. Compared with gear transmission, chain transmission requires lower manufacturing and installation accuracy, and its transmission structure is simple when the center distance is large. Disadvantages of chain transmission-the instantaneous chain speed and instantaneous transmission ratio are not constant, the transmission stability is poor, and there is a certain impact and noise in the work.

9. The role of the shaft, the difference between the rotating shaft, the transmission shaft and the mandrel

A shaft is a mechanical part used to support rotation. The shaft transmits both torque and bending moment. The drive shaft only transmits torque without bearing or small bending moments. The mandrel is only subjected to bending moments and partly transmits torque.

10. Structural requirements of shaft

(1) The shaft shall be easy to process, and the parts on the shaft shall be easy to assemble and disassemble.

(2) The shaft and the parts on the shaft must have accurate machining positions

(3) Each part must be firmly and reliably relatively fixed

(4) Improve the force situation and reduce stress concentration.

11. Necessary conditions for the formation of a dynamic oil film

(1) There must be a wedge-shaped gap between the two working surfaces

(2) The two working surfaces must be continuously filled with lubricant or other viscous fluid

(3) There must be a relative sliding speed between the two working surfaces, and the direction of movement must allow the lubricating oil to flow in from the large section and the small section to flow out. In addition, for a certain load, the speed, viscosity and clearance must be matched properly.

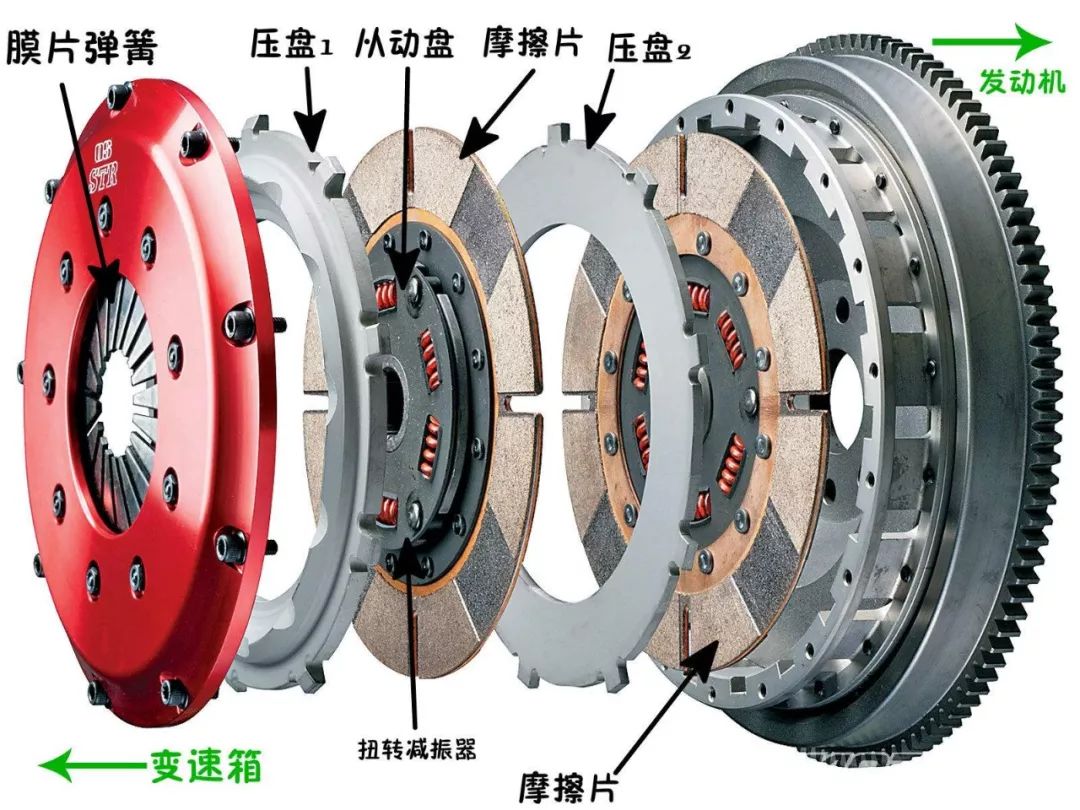

12. Connections and differences between couplings and clutches

Both are mainly used for the link between the shaft to make them rotate together and transmit torque. The two shafts connected with the coupling can only be separated after the machine is stopped and after disassembly. The two shafts connected by the clutch can be easily separated or engaged during machine work.

13. Characteristics of fatigue fracture of parts under variable stress

(1) The maximum stress for fatigue fracture is much lower than the strength limit of the material under static stress, and even the yield limit is low. (2) Regardless of brittle materials or figurative materials, the fatigue fracture openings show sudden brittle fracture without obvious plastic deformation. 3) Fatigue fracture is the accumulation of damage.

14. The main types of mechanical wear

Abrasive wear, adhesive wear, fatigue wear, corrosion wear

15. The role of the washer

Increase the support area of the coupled member to reduce the pressure at the contact and avoid scratching the surface of the coupled member when tightening the nut

16. Pros and cons of rolling spirals

Advantages: (1) the wear is small, and the adjustment method can be used to eliminate the clearance and generate a certain pre-deformation to increase the stiffness, so its transmission accuracy is very high; (2) it does not have self-locking properties, and can change linear motion into rotational motion.

Disadvantages: (1) complicated structure, difficult to manufacture, and (2) some mechanisms need to add a self-locking mechanism to prevent reverse.

17. Effect of error on transmission in gear transmission

(1) Affect the accuracy of the transfer motion, (2) The instantaneous transmission ratio cannot be kept constant, affect the smoothness of the transmission, and (3) affect the uniformity of the load distribution.

18. Geared power loss includes

Friction loss in meshing, oil resistance loss in agitated lubricating oil, friction loss in bearings.

19. Advantages and disadvantages of single arc gear

Advantages: (1) the contact strength of the tooth surface is high, (2) the shape of the tooth profile is beneficial to lubrication and high efficiency, (3) the tooth surface is easy to saturate, (4) there is no undercut, and the number of tooth surfaces can be less.

Disadvantages: (1) The accuracy of the center distance and the depth of the teeth is high. The error between the two significantly reduces the load carrying capacity of the transmission. (2) The noise is large, and its application is limited in high-speed transmission. (3) Usually the wheel Tooth bending strength is low. (4) To cut convex arc tooth profile and concave arc tooth profile with the same modulus, the same hob is used.

20. Bearing material properties

(1) Low friction coefficient

(2) Good thermal conductivity and small thermal expansion coefficient

(3) Abrasion resistance, corrosion resistance, strong anti-gluing ability

(4) Sufficient mechanical strength and plasticity