Fixture design

Part process analysis

By analyzing the structure and process characteristics of the parts, it can be seen that the cast aluminum motor housing has a special-shaped polyhedron structure, and the machining surfaces are in a 90° relationship. In the absence of a five-axis CNC machining center, the machining process analysis of the cast aluminum motor housing with high requirements and difficulties was carried out, the processing steps were determined, and a pneumatic turning fixture was designed to achieve three-axis Processing is carried out on the linked CNC machining center.

The process is as follows: Process 1, using a general vise clamp on another processing center to complete the processing, and pre-processing A and B in the processing process as a post-processing process positioning pin (the two Product performance and appearance have no effect); Process 2 and Process 3 (see the figure below), the clamping is completed on the pneumatic turning fixture of this design.

2, The working principle of the fixture

According to the structural characteristics of the parts, according to conventional processing, when the process 2 and process 3 are completed, it needs to be clamped twice to complete, and the position accuracy of each adjacent surface must also be guaranteed. For this purpose, a pneumatic turning fixture capable of processing 4 parts at the same time is designed and installed in the processing center for processing.

This set of clamps is mainly composed of a bottom plate, a movable turning table, a rotating supporting shaft, a supporting plate, a V-shaped guide limit supporting block, a turning cylinder and a steering cylinder. Among them, the bottom plate is fixed in the T-slot of the machine tool, and the movable turning table is connected to the rotating support shaft through the bearing, and then is installed on the bottom plate together with the supporting plate, and connected by a cylinder with turning, to realize the movable turning table to form a horizontal state or vertical On the spindle. Cylinders for steering and compaction are installed on the movable table, which clamps the workpiece. All cylinders are connected in groups by air pipes.

3. The working principle of the fixture

In order to ensure the positioning accuracy of the flip table, a total of 4 sets of V-shaped guide limit support blocks are designed for the left and right groups, which can not only achieve bidirectional positioning horizontal and vertical position limitation, but also serve as auxiliary support The effect of force improves the rigidity of its movable turning table, and plays the role of stroke limit for the turning cylinder; at the same time, it can also adjust the accuracy during the actual processing process, because the movable turning table may be used in the actual process A small amount of deformation will occur with the time of stress.

The movement of the cylinder for turning is designed at the lower part of the center of the movable turning table. In addition to balancing the thrust, it can also be used as an additional support to better maintain the rigidity of the movable turning table, while saving working space and shrinking unnecessary. Processing avoidance.

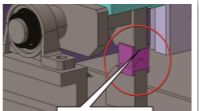

The parts are positioned and clamped on the movable turning table with one side and two pins, and the clamping of 4 workpieces is completed at the same time by turning and pressing the cylinder. In the fixture design, the use of steering compression cylinder to compress the workpiece can better save the space occupied during clamping, improve the efficiency of clamping and replacing the workpiece, and more importantly, the clamping force can be adjusted finely, not to Crush the work piece or deform it. When assembling and disassembling the workpiece, a total of 10 steering and compression cylinders on the upper and lower sides simultaneously lift or press the pressure block, so that there is room for taking parts. Tight effect. The state before and after the steering compression cylinder is compressed is shown in the figure below.

4. Use of fixtures

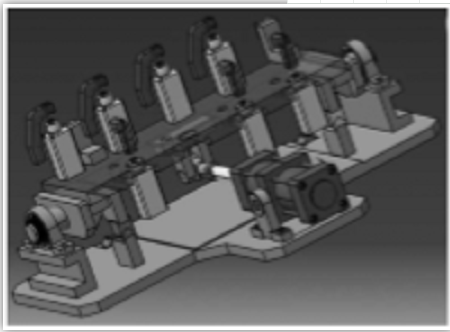

When the cylinder for turning over the jig is pushed out, the steering and compression cylinder is opened, and the parts are positioned and clamped through one side and two pins. After the steering and compression cylinder is closed, the workpiece is pressed and the turning cylinder is kept pushed out. At this time, the V-shaped guide limit on the back of the workpiece The position support block is completely fitted. Start the CNC to perform this surface processing. The state of the fixture in step 2 is shown in the figure below.

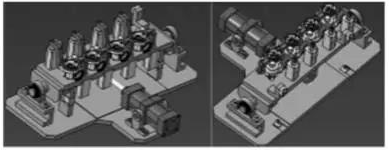

After machining the above surface, the pressing action of the steering and compression cylinder remains unchanged, and the cylinder for turning is contracted, so that the movable turning table is turned by 90°, and the vertical guide is supported by the V-shaped guide limit support block on the side of the workpiece to ensure its verticality. Degree and the displacement error before and after rotation, so that two processes of one clamping process are realized at one time, thereby reducing the loss of accuracy with high efficiency and maximum. The state of the jig in step 3 is shown below.

The processing of the above-mentioned workpieces is completed at one time by the forming knife. Because the part itself is an aluminum casting shell, it has thin walls, special shapes, less machining allowance, and roundness requirements. If the walking trajectory is used for circular processing, it will produce deformation during processing and ellipse in the finished product; The axis of rotation processing, the obtained circle size will be more round than the trajectory, and can make the processing faster, the processing shell circle points are balanced, so as to ensure the processing accuracy and production efficiency.

In CNC machining, pneumatic fixtures have become a very wide way of clamping, and are being used more and more in the actual casting processing. It is more convenient to manufacture, fast clamping, and more suitable for large quantities of parts. Processing, so we must vigorously develop pneumatic fixtures, through pneumatic fixtures to better match CNC processing, it can better improve production efficiency and processing accuracy.